Sugar factory processes involve cane related activities starting from cane plantation to cane delivery. The current procedure to do these activities is quite paper consuming. Due to extensive paper work relative to cane and data duplication, the process becomes tedious. The information keeps repeating at every stage of cane plantation and continues till the delivery stage. The process has another shortcoming; as the data is not always available to the concerned members. For example, if any member or a farmer needs information such as schemes availed, items purchased through society, the member needs to go to the factory or the factory center.

Thus there is a need to automate the complete process from cane plantation to delivery stage of the cane and settlement to the farmer. It is also necessary to overcome manual errors and provide feasibility to the farmer; to know all the schemes availed till date, and make the whole process user friendly on both ends.

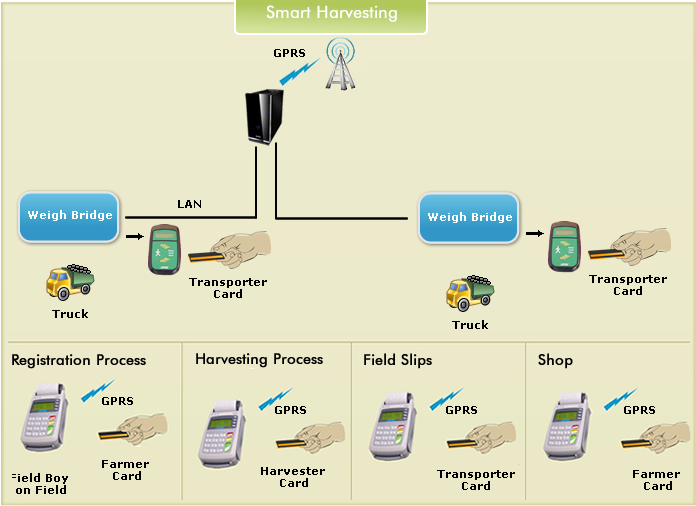

The harvesting PDA developed by Aftek addresses the need mentioned above; from the first stage to the final stage of delivery.

In the proposed scheme, the data digitization will overcome the paper work and data duplication; members can obtain factory related information at any time. This scheme will also reduce the cost for maintaining factory records. The automated process reduces the manual errors and related losses.

- Registration of plots

- Smart cards are assigned to farmers after registration of plots with the factory

- Card includes details like - type of irrigation system, plot boundaries, plot type, scheme availed by the farmer, seeds, crop maturity date, schedule for harvesting.

- Harvesting

- Harvester has a smart card

- As per the harvesting schedule, the field person verifies the land for quality and % of irrigation

- Harvester code is entered in the PDA and a harvest slip is generated for the farmer

- Transportation

- Bundles (or ropes) are loaded on the vehicle and the trip information is generated

- Data such as rope owner, rope position in the vehicle are stored in the device and the smart card

- Transporter is assigned a smart card

- Aftek's smart PDA reader reads the transporter card and records the weight of the truck and the rope

- PDA calculates the amount to be paid to the farmer after deducting the amounts to be given to the transporter and harvester; this amount is credited to the bank

- C, C++, MFC

- .NET

- Embedded Linux

- Hardware architecture design and development

- Arm developers suite

- Serial

- PSTN

- GPRS

- GSM

- Maintains the records of several members

- Overcomes the paper work and data duplication

- Makes the factory information easily available

- Reduces the cost of stationery

- Minimizes the manual errors

- Serial transmission of master data from the factory server to the PDA

- Embedded 'C' language for development and windows DLL

- Support for TXT and DBF files for client interface